No entry last week because I just flat ran out of time.

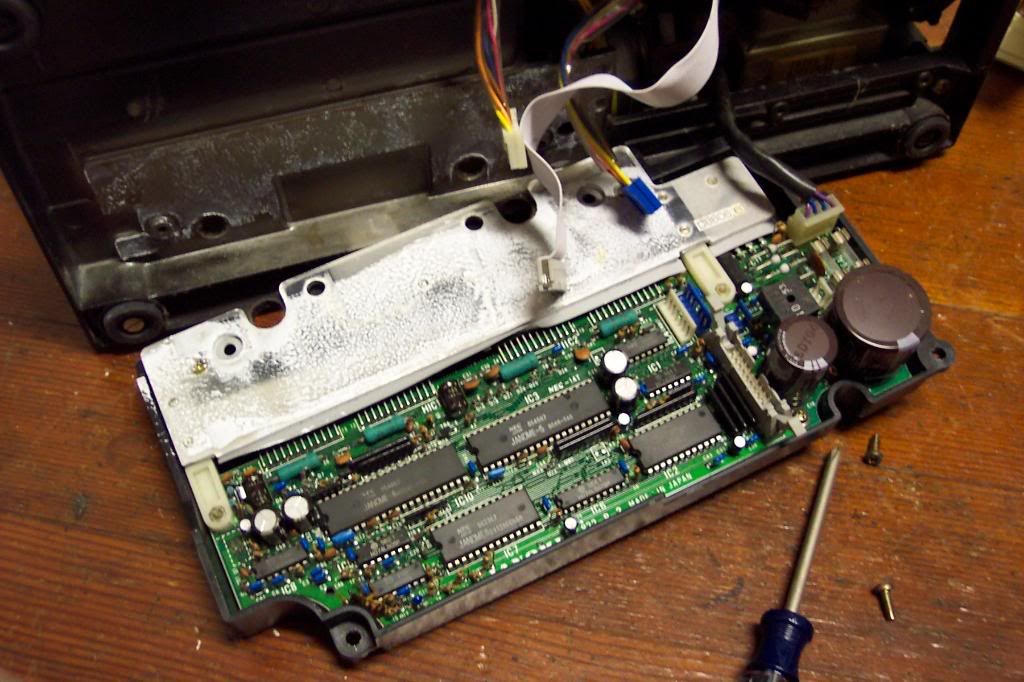

Somewhere between last Saturday and today was the first anniversary of me keeping records of my junk disassembly hobby. So, I figured I'd use the occasion to post about a phone I took apart several years ago. This was the first time I had attempted to document the taking apart process, from complete appliance to pile of parts.

This is from November 2004, about a month before I moved to Hawaii, hence all the boxes and stuff in the background. If I remember correctly, I had set the table up to sort out erector set parts for sale, then realized I had a broken phone, and decided to take it apart.

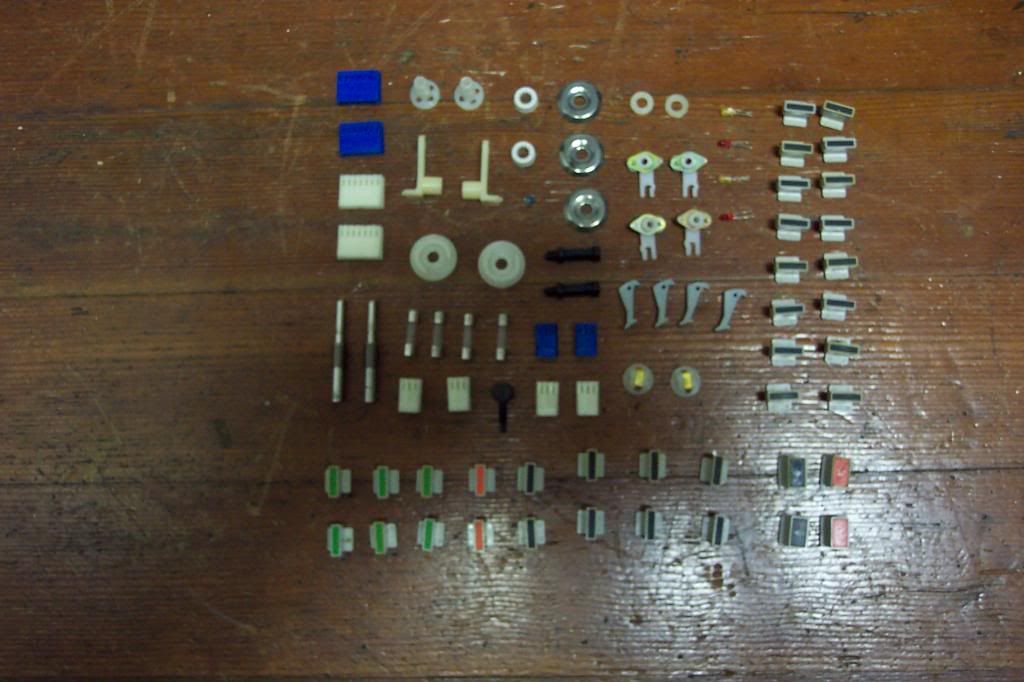

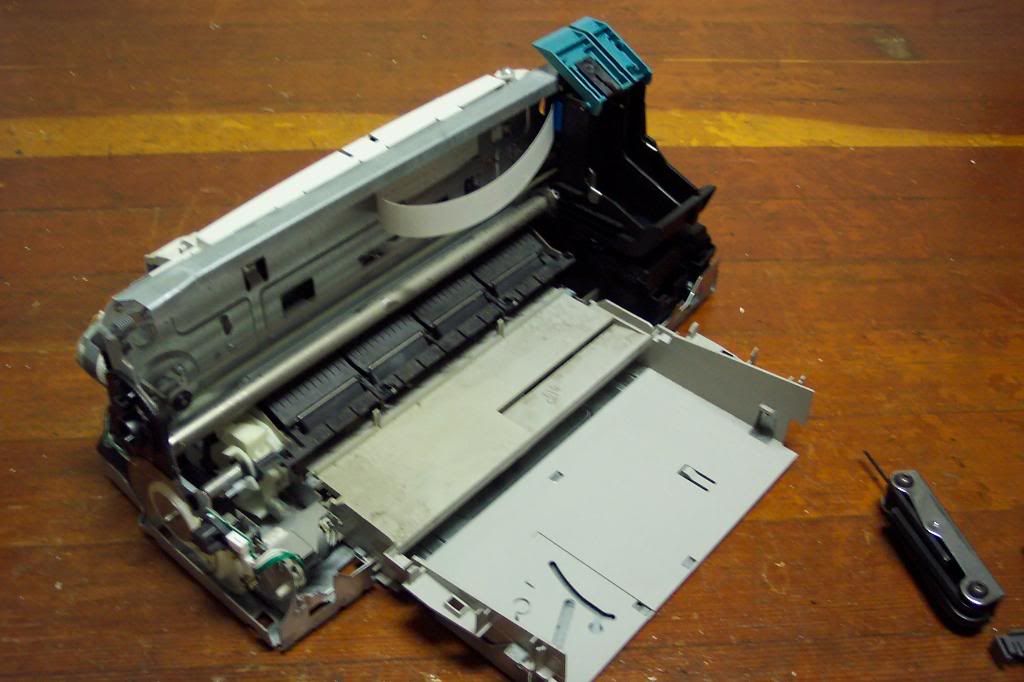

I didn't think/bother to document the process, so the documentation sort of skips to an end shot of all the parts. For some reason, I didn't separate the parts I kept with the ones I trashed. If I remember correctly, I kept the housing of the cradle, the cradle's antenna, and possibly the receiver housing. It's been a while, and not all of my junk is in the same place. Also, it seems like my photography skills have not really improved in 4 years.

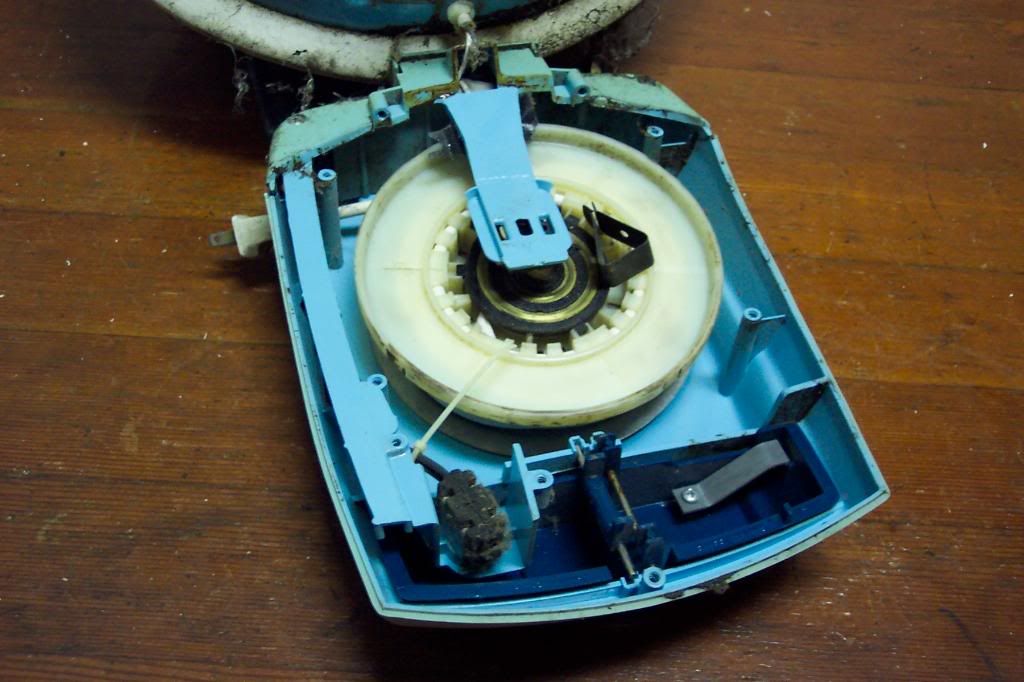

As I was taking the phone apart, I decided the cradle housing looked sort of vehicular, so I got out my collection of broken toy parts to mock up a dune buggy/ATV type configuration. The white thing on top is a piece of cardboard, and the two (well one and a half, anyway) action figures were there to try to work out the best scale.

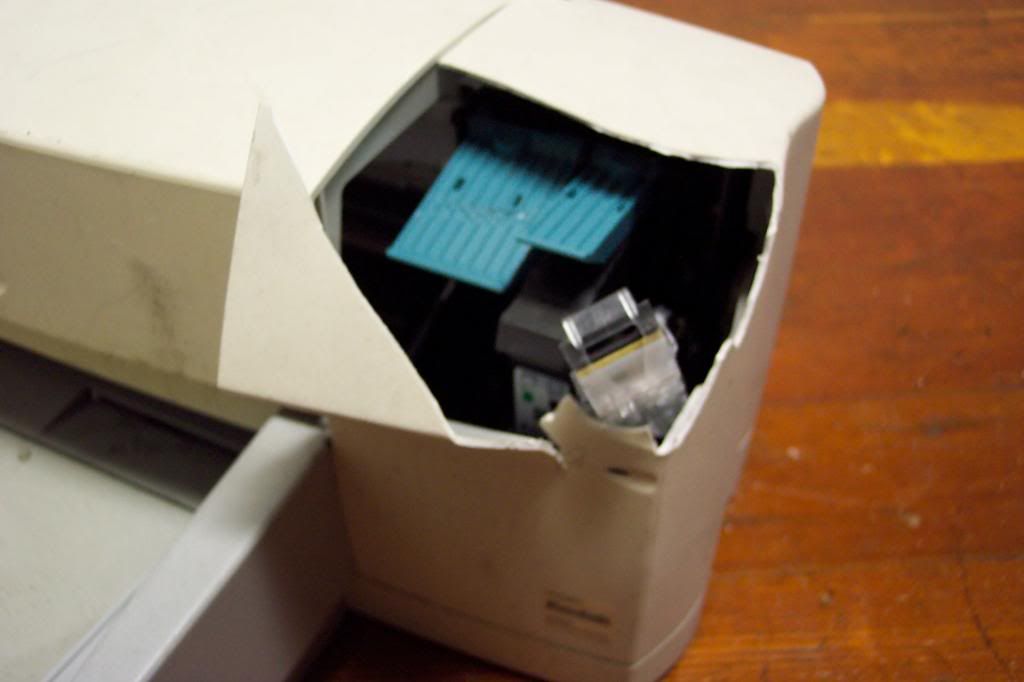

I made a crude mock-up in MS Paint to show where I wanted the wheels (black rectangles) and engine (grey rectangle). Unfortunately, the project has yet to move past the vague design stage. I should still have all the parts, so I may get back to it once I move to an apartment that's a bit more conducive to hobby work..