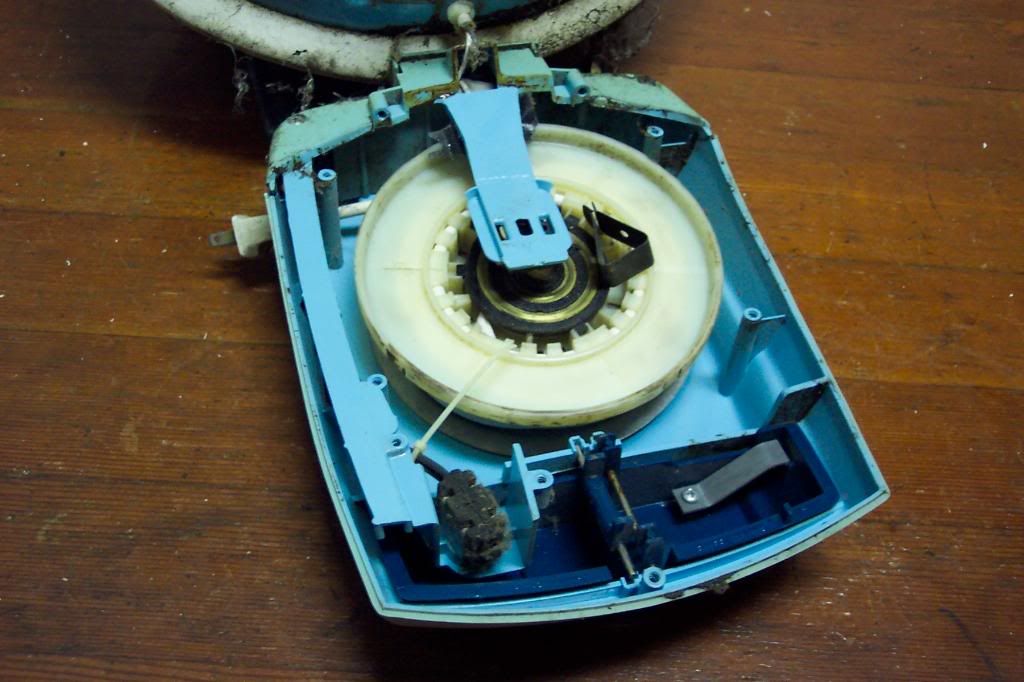

Okey, let me get this out of the way: Holy crap, it's a Betamax player! I've never even seen one of these up close, let alone had a junker to take apart. And how I found it is kind of weird too. It was just sitting in the grass outside the 7-11 on the corner, all by itself, with no other junk anywhere near it. It was upside down, with the unpainted steel bottom tricking me into thinking it was some sort of traffic monitoring device at first. It was only on the way back home that I decided to flip it over and see what it actually was.

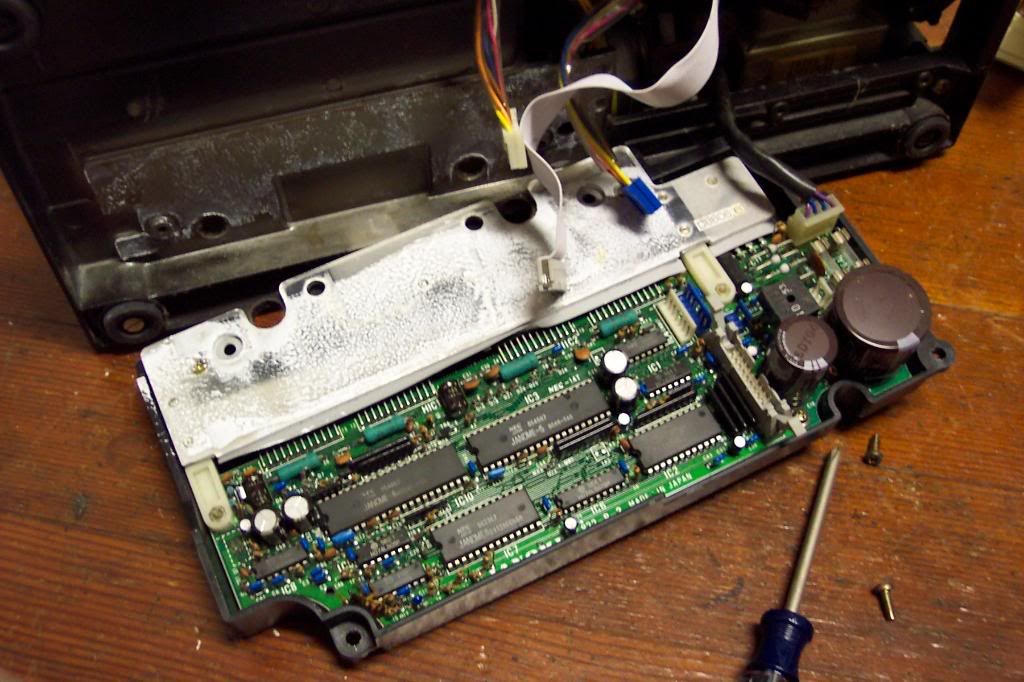

To my non-engineer's eye, all the parts inside look familiar, yet slightly askew, like a fast food franchise in a foreign country. That makes sense, I guess, since the process for playing both Betamax and VHS is basically the same. I honestly don't remember why this is the only picture of the inside that I took; I guess I didn't think about it until I was already done.

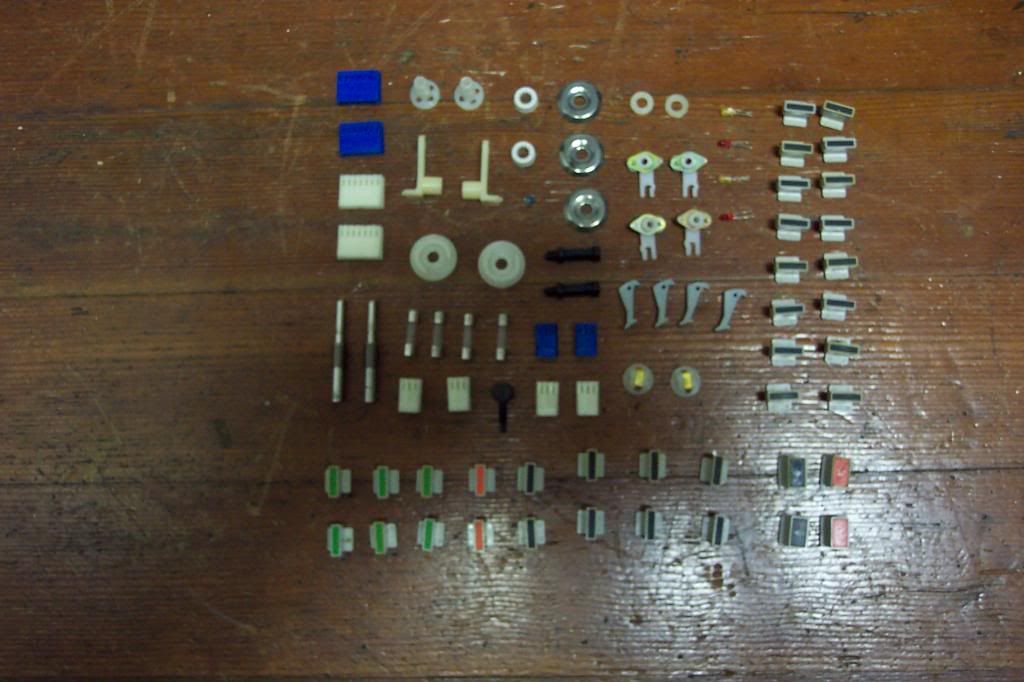

A pretty good assortment of parts, though none of them strike me as really eye-catching or otherwise interesting beyond where they came from. That could be a good thing, since I doubt I'll ever see another Betamax player.